Common Challenges in GMP Contract Manufacturing

Compliance Risks

●Some CMOs fail to strictly adhere to GMP standards, leading to audit failures or product recalls.

●Incomplete documentation (e.g., missing batch records, insufficient process validation) hinders regulatory submissions.

Inconsistent Quality Control

●Significant batch-to-batch variability (e.g., RSD >5% for content uniformity, dissolution rate deviations).

●Cross-contamination risks (especially in multi-product lines with inadequate cleaning validation).

Supply Chain Vulnerabilities

●Unaudited raw material suppliers causing fluctuations in critical excipients (e.g., film-forming agents).

●Capacity shortages or scheduling conflicts delaying product launches.

Technology Transfer Failures

●Lab-scale processes not replicable in production (e.g., spray-drying parameter drift).

●Lack of flexible production capabilities for specialized formulations (e.g., multilayer ODFs).

Why Choose Us

Flawless GMP Compliance

●Full documentation suite (DQ/IQ/OQ/PQ) for global regulatory support.

Precision Quality Assurance

●Dedicated isolation lines for high-potency or allergen-sensitive products, eliminating cross-contamination.

End-to-End Supply Chain Security

●Flexible Ordering: Start with as few as 1,000 films—ideal for testing and small-scale production.

Technology-Driven Partnership

●Proprietary ODF technologies (e.g., low-temperature drying to preserve protein integrity).

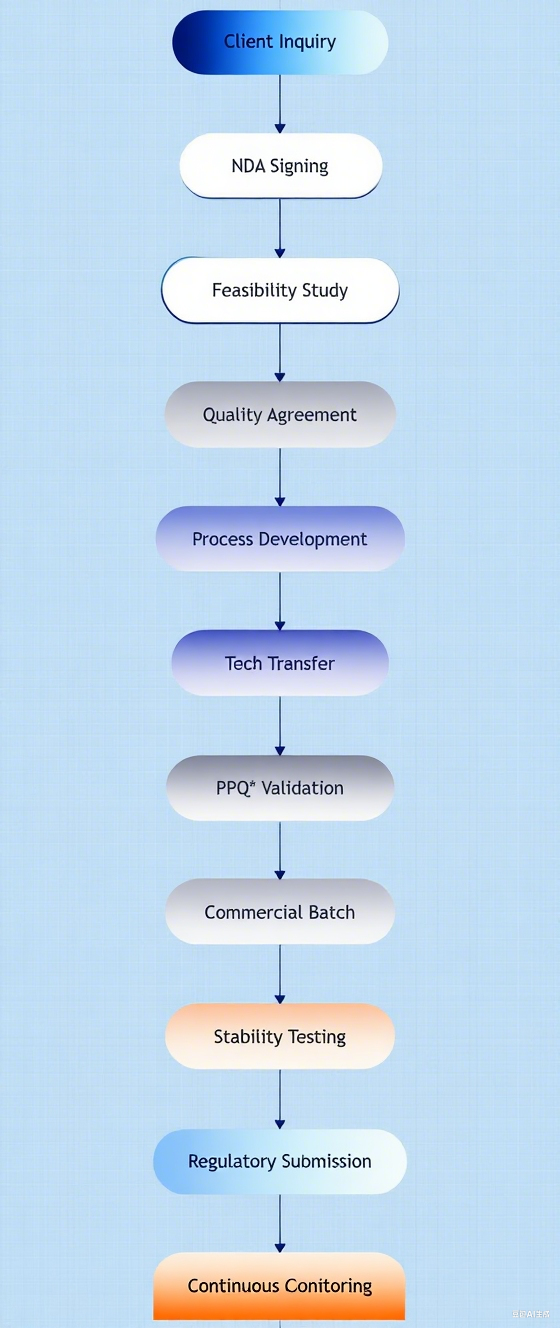

●Full-cycle support from formulation optimization to commercialization, with 100% tech transfer success.