TMY-800H Automatic Foil Stamping & Die-cutting Machine TMY-800H Automatic Foil Stamping

Short Description:

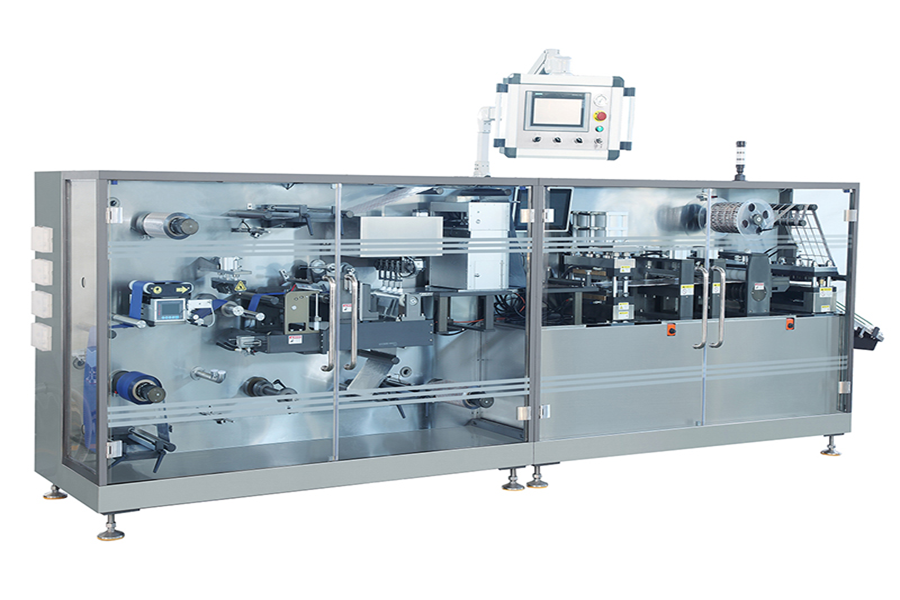

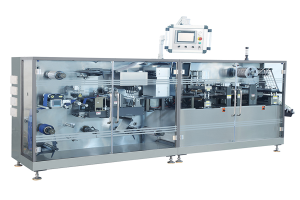

It is a special equipment for laying liquid materials evenly on the base film to make thinner film materials, and adding a laminated film on it. Suitable for medicine, cosmetics, and health care products industries.

The equipment adopts frequency conversion speed regulation and automatic control technology integrated with machine, electricity and gas, and is designed in strict accordance with the “GMP” standard and “UL” safety standard of the pharmaceutical industry. The equipment has the functions of film making, hot air drying, laminating, etc.

Product Video

Sample Diagram

Performance & Features

1.It is suitable for the composite production of paper, film, and metal film coatings.The power system of the whole machine adopts a frequency converter stepless speed regulation system. Unwinding adopts magnetic powder brake tension control

2. Adopt main body plus accessory module structure, each module can be disassembled and installed separately. Installation using cylindrical pin positioning, screw fixation, easy assembly.

3. The equipment has automatic working length recording and speed display.

4. Independent partition of drying oven, with independent automatic control of temperature, humidity, concentration and other functions, to ensure efficient and high quality production.

5. The lower transmission area and upper operation area of the equipment are completely sealed and isolated by stainless steel plates, which avoids cross-contamination between the two sections when the equipment is working, making it easier to clean.

6. All the parts in contact with the material, including the pressing roller and the drying tunnel, are made of stainless steel and non-toxic materials, which meet the requirements and specifications of "GMP". All electrical components, wiring and operation schemes comply with "UL" safety standards.

7. Equipment emergency stop safety device, improve the safety of the operator in debugging and mold change.

8. It has a one-stop assembly line for unwinding, coating, drying, laminating and rewinding, with smooth technology and intuitive production process.

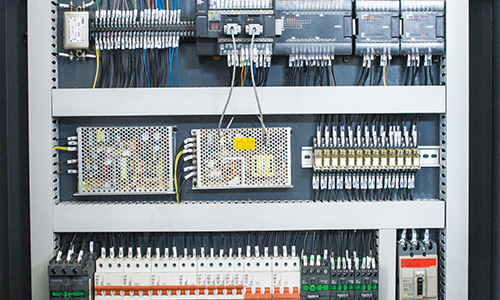

9. The switchboard adopts split structure, and the drying area can be customized and lengthened to make the operation more smooth.

Work station details

The ODF Making Machine employs various modules to accomplish its task.

The primary labor modules include:

① Winding/Unwinding Station

● Place the PET roll on the Air Expansion Shaft and inflate it to secure the film;

● The traction mechanism pulls the material from the reel into each station;

● One side of the Air Expansion Shaft is connected to the Magnetic Powder Brake;

● Adjust the controller to achieve precise tension control based on the unique material and tension requirements.

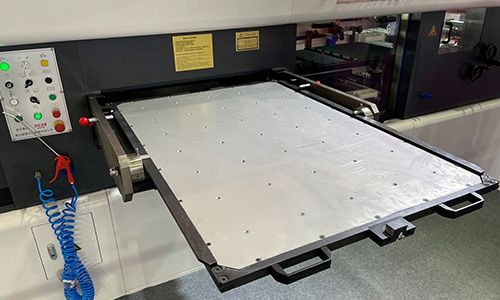

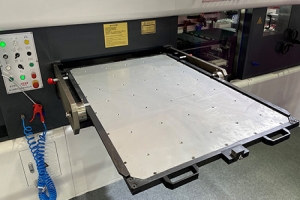

② Film Making Station

● Used to adjust the horizontal balance of the coating roller,which can affect the film's thickness;

● Through a specific scraper,evenly distribute the liquid material to the base film;

● Fix the position of the two baffles,and adjust the film width of the coating.

③ Film Drying Station

● Air Inlet Bellows Greenhouse is heating by external stainless steel heater;

● The drying area using asbestos(Aluminum silicate refractory fiber)to preserve heat,and the temperature is controlled by PLC panel;

● Heating temperature arrangement at 30~100±0.5℃,with automatic proportional temperature control.

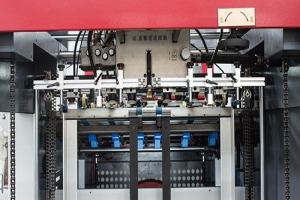

④ Traction Module

● Composed of rubber roller,pneumatic components,steel roller and drive system;

● Traction roller has a surface covered with EPDM rubber,with a hardness of Shaw 75 to 80 degrees;

● Cylinder is equipped with a swing arm pressure roller,allowing pressure adjustment.

Technical Parameters

| Production width | 280mm |

| Roll surface width | 350mm |

| Speed | 1m-2.5m/min Depends on the actual material and status |

| Unwinding diameter | ≤φ350mm |

| Rewinding diameter | ≤φ350mm |

| Heating and drying method | Built-in hot air drying, centrifugal fan hot air exhaust |

| Temperature control | RT-99℃ ±2℃ |

| Edge thickness | ±1.0mm |

| Power | 60KW |

| External dimensions | 9000*1620*2050mm |

| Voltage | 380V 50HZ |

Previous:No Information

Next:MYR-1060DEEP AUTOMATIC HOT EMBOSSING & DIE-CUTTING MACHINE(HEAVY)