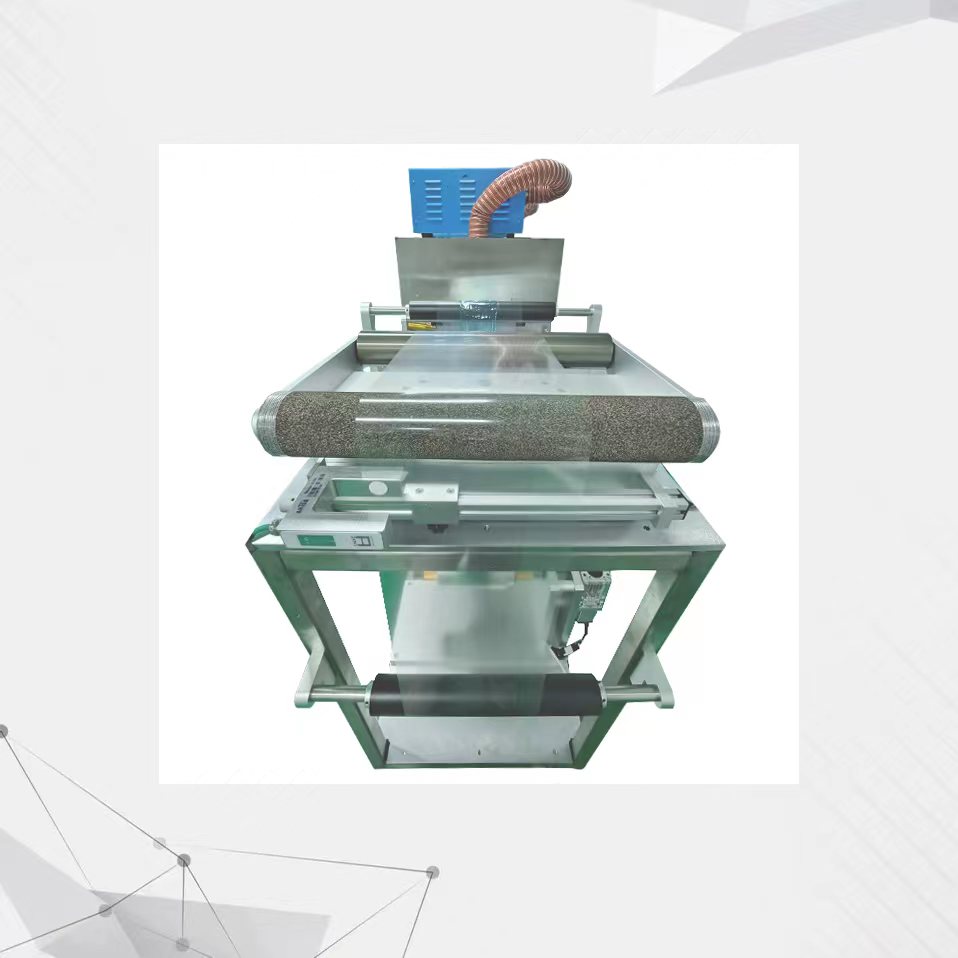

OZM-120 Oral Dissolving Film Making Machine (Lab Type)

Short Description:

This precision coating machine utilizes advanced micro-metering technology to uniformly deposit active pharmaceutical solutions or powdered formulations onto polymer film substrates, achieving a highly consistent coating thickness with ≤±3% deviation. The system's multi-zone temperature-controlled drying mechanism ensures optimal solvent evaporation rates while maintaining API stability, producing finished films with precise dosage uniformity meeting USP <905> specifications for oral dissolvable films, transdermal patches, and other thin-film drug delivery systems.

Product Video

Sample Diagram

Performance & Features

The oral film making machine can be used in product manufacturing within the pharmaceutical, cosmetic, and food industries. If you need to produce patches, oral soluble film strips, mucosal adhesives, masks, or other types of coating products, our film making machines can always operate stably to achieve high-precision coating. Even complex products whose residual solvent levels must meet strict limits can be produced using our oral film making machine.

This machine uses a frequency converter for speed regulation, integrates the automatic control functions of the main machine, electricity, and compressed air, and complies with GMP standards and UL safety standards. It adopts a PLC control system to complete the preparation and drying processes of oral films, enabling easy and accurate control.

Work station details

●The oral dissolving film making machine is suitable for the composite production of paper and film coatings. The power system of the whole machine adopts a servo drive speed regulation system, and unwinding uses magnetic powder brake tension control.

●This pharmaceutical equipment is equipped with automatic working length recording and speed display functions.

●The drying oven adopts the heating method at the bottom of the flat plate, with temperature controlled by PID and a control accuracy of ±3℃.

●The rear conveying part of the equipment is completely sealed and isolated from the front operation area by stainless steel plates, avoiding cross-contamination between the two areas during operation, and it is convenient to clean.

●All parts in contact with materials, including pressing rollers and drying tunnels, are made of stainless steel and non-toxic materials, in line with the requirements and specifications of GMP (Good Manufacturing Practice). All electrical components, wiring, and operating schemes comply with UL safety standards.

●The emergency stop safety device of the equipment improves the safety of operators during debugging and mold changing.

●This equipment is equipped with a one-stop production line for unwinding, coating, drying, and winding, with a smooth process and an intuitive production process.

Technical Parameters

| Effective production width | 120mm |

| Roll width | 140mm |

| Mechanical speed | 0.1-1.5m/min (Depending on actual material and status) |

| Unwinding diameter | ≤⌀150mm |

| Rewinding diameter | ≤⌀150mm |

| Heating drying method | Plate heating, centrifugal fan for hot air exhaust |

| Temperature control | Room temperature: -100℃±3℃ |

| Reel edge | ±3.0mm |

| Total power | 5kW |

| Dimensions | 1900*800*800mm |

| Weight | 300kg |

| Voltage | 220V |

Previous:MYR-1060DEEP AUTOMATIC HOT EMBOSSING & DIE-CUTTING MACHINE

Next:No Information